| Alloy wheel repair machine | AWR22 | AWR25 | AWR28 | AWR32 | |

| CNC controller | Touch Screen Operation 17" LCD Display | ||||

| Max. swig over bed Dia. | 610 | Φ635 | Φ770 (30’) | Φ880(34’) | |

| Max. Load alloy wheel Size | 22inches | 22 inches | 28 inches | 32 inches | |

| Adjustable stroke of carrier in X direction | 100mm | 100mm | 100mm | 100mm | |

| Cross slide travel (mm) | 300 | 320 | 390 | 450 | |

| Width of the rail (mm) | 260 | 300 | 330 | 400 | |

| Length of the rail (mm) | 500 | 700 | 750 | 750 | |

| Clamping type | 10' chuck /self-centering wheel clamping | 12' chuck/self-centering wheel clamping | 16' chuck/self-centering wheel clamping | ||

| Probe type | Probe or laser | ||||

| Range of spindle speed (RPM) | 50~2500 | 50~2500 | 50~2000 | 50~1800 | |

| Spindle speed control | Automatic | Automatic | Automatic | Automatic | |

| Spindle bore (mm) | Φ60 | Φ60 | Φ82 | Φ82 | |

| Max. size of tool post | 25×25mm | 25×25mm | 25×25mm | 25×25mm | |

| Stations of tool carrier | 4 position | 4 position | 4 position | 4 position | |

| Min. setting unit of motor | (Z) long 0.001mm | ||||

| (X) cross 0.001mm | |||||

| Moving speed of post | (Z) long 8m/min | ||||

| (X) cross 6m/min | |||||

| Motor power | 4KW | 4kw | 5.5KW | 7.5KW | |

| Surface roughness | Ra 0.8-1.6 | ||||

| Machine size | (L×W×H) (mm³) | 1900*1400*1750 | 2100*1500*1750 | 1990 ×1600×1860 | 2470×1660×2080 |

| Package size(mm) | 2000*1400*1750 | 2200*1500*1950 | 2150×1750×2100 | 2620×1810×2300 | |

| Net weight | 1300kg | 1700kg | 2000kg | 2500kg | |

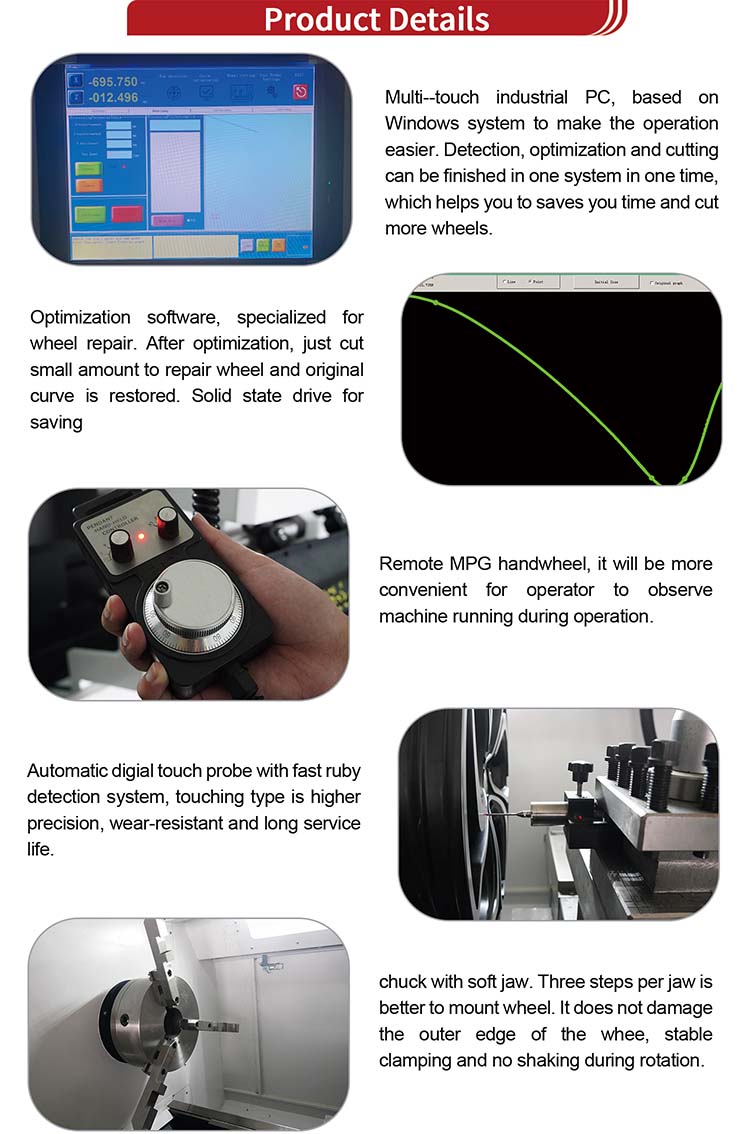

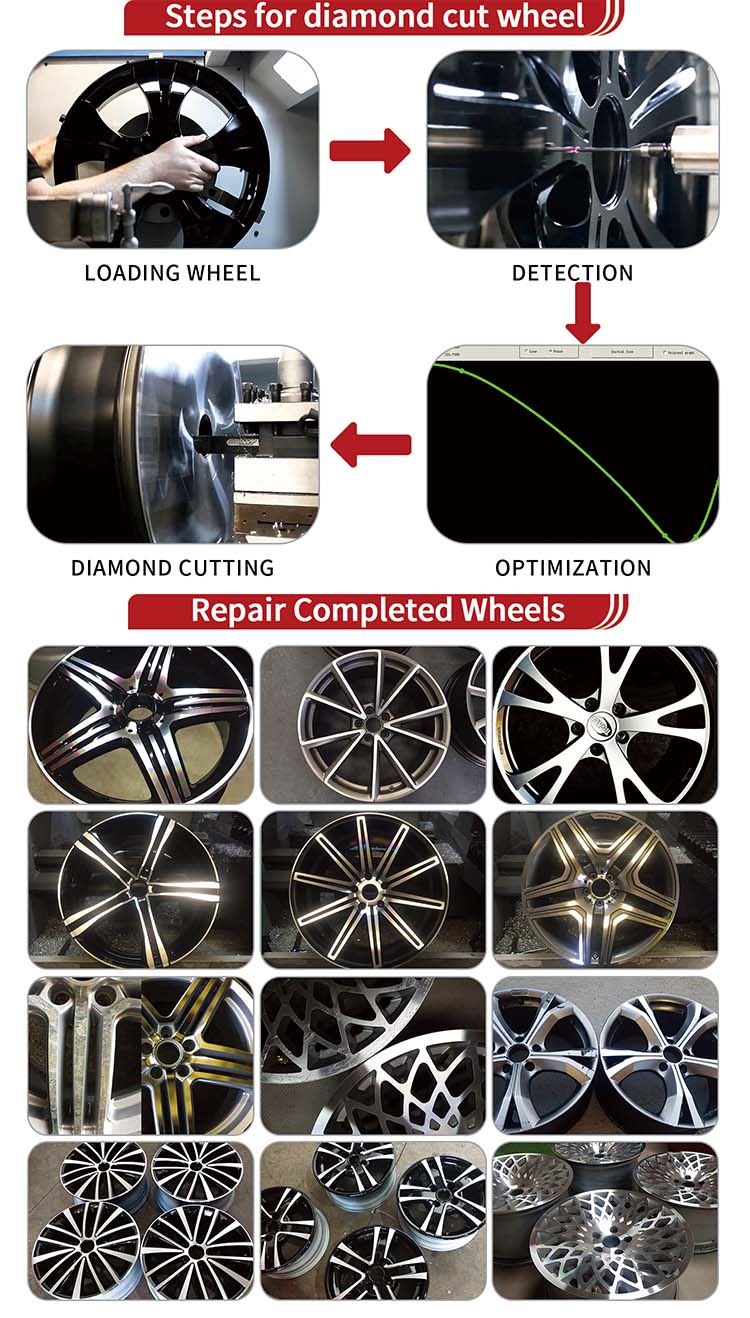

1. Loading wheel: Put the wheel hub to be repaired in the correct position. 2. Detection, infrared probe detects the surface of the hub. 3. Optimization, a dedicated operating system analyzes and integrates data. 4. Diamond cutting, start turnin processing.

1. Loading wheel: Put the wheel hub to be repaired in the correct position. 2. Detection, infrared probe detects the surface of the hub. 3. Optimization, a dedicated operating system analyzes and integrates data. 4. Diamond cutting, start turnin processing.