| Model | C6 1/2 40C | ||

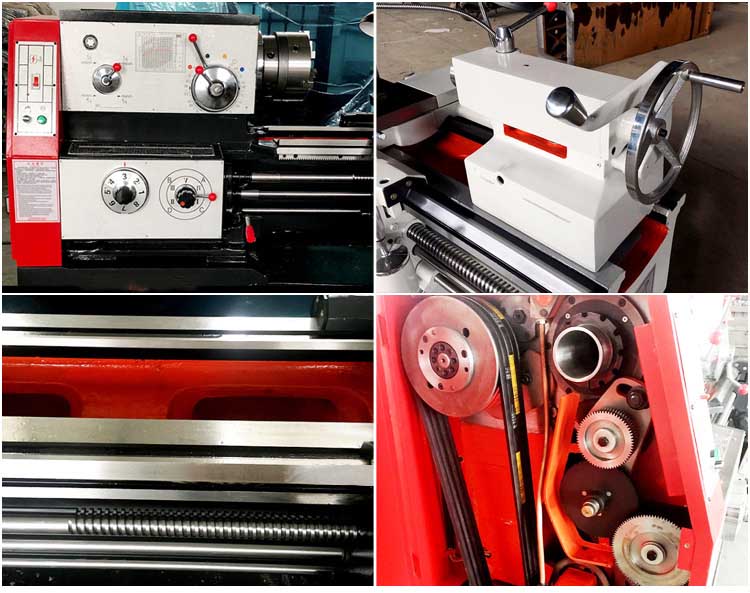

| Processing capacity | Max swing diameter over bed | 400 | |

| Max.swing over cross slide | 230 | ||

| Maximum turning diameter at the saddle Maximum turning diameter at the saddle

| 560 | ||

| Center distance | 750, 1000, 1500 | ||

| Width of bed | 360mm | ||

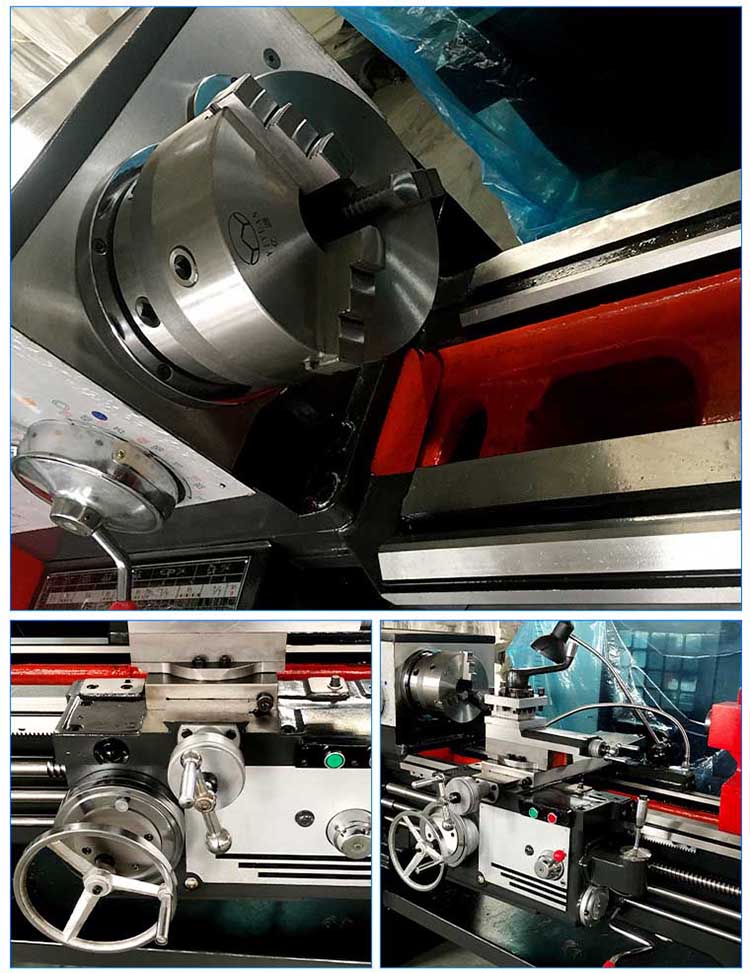

| Spindle | Spindle bore | Φ52/80mm | |

| Spindle nose | C6 | ||

| Spindle taper | MT6 | ||

| Spindle speeds range(Steps) | 40-1400 (9steps) | ||

| Feed | Metric threads(Number ) | 0.25-14mm (19kinds) | |

| Inch threads(Number ) | 2-40/inch | ||

| Modular threads(Number ) | 0.25-3.5mπ (11kinds) | ||

| Carriage | Cross slide stroke

Cross slide stroke

| 180mm | 222mm |

| Tool rest stroke Small tool rest stroke

Small tool rest stroke

Small tool rest stroke

Small tool rest stroke

Small tool rest stroke

Small tool rest stroke

Small tool rest stroke

| 95mm | ||

| section dimension

| 20 x 20mm² | ||

| Tailstock | Taper of tailstock sleeve | MT4 | |

| Diameter of tailstock sleeve | 65mm | ||

| Stroke of tailstock sleeve | 140mm | ||

| Main motor | 4kw | 5.5kw | |

| Package size: (L x W x H) |

| ||

| Center distance 750mm | 2220 x 1150 x 1590mm | ||

| 1000mm | 2470 x 1150 x 1590mm | ||

| 1500mm | 2970 x 1150 x 1590mm | ||

| Weight: NW/GW (KG) |

| ||

| Center distance 750mm | 1400 | 2050 | |

| 1000mm | 1500 | 2150 | |

| 1500mm | 1650 | 2300 | |

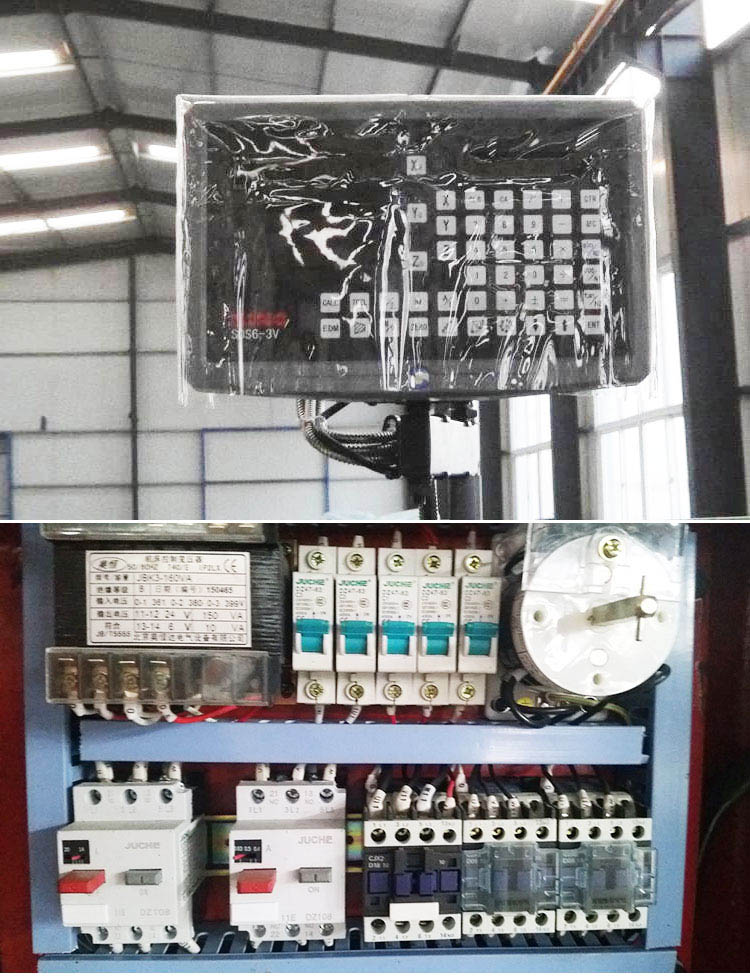

1. Add appropriate grease according to the lubrication chart of the machine tool. 2. Check all electrical facilities, handles, transmission parts, protection and limit devices are complete, reliable and flexible. 3. Each gear should be at the zero position, and the belt tightness should meet the requirements. 4. It is not allowed to store metal objects directly on the bed surface to avoid damage to the bed surface. 5. The workpiece to be processed is free of mud and sand to prevent mud and sand from falling into the carriage and damaging the guide rail. 6. An empty test run must be carried out before the workpiece is not clamped, and the workpiece can be installed after confirming that everything is normal.

1. Add appropriate grease according to the lubrication chart of the machine tool. 2. Check all electrical facilities, handles, transmission parts, protection and limit devices are complete, reliable and flexible. 3. Each gear should be at the zero position, and the belt tightness should meet the requirements. 4. It is not allowed to store metal objects directly on the bed surface to avoid damage to the bed surface. 5. The workpiece to be processed is free of mud and sand to prevent mud and sand from falling into the carriage and damaging the guide rail. 6. An empty test run must be carried out before the workpiece is not clamped, and the workpiece can be installed after confirming that everything is normal.