| Item | CK6150A |

| Max. swing dia. over bed | Φ500mm |

| Max. swing dia. over cross slide | Φ280mm |

| Processing length | 1500mm |

| Width of the bed | 400mm |

| Dia. of spindle | Φ82mm |

| Spindle taper | 1:20/Φ90 |

| spindle nose | Type of spindle head D-8 |

| Spindle speed | 14-1500rpm |

| Spindle speed step | step-less |

| chuck size | 250mm |

| Tool holder | 4 station |

| Tool bar section | 25X25mm |

| Main motor power | 7.5KW |

| X/Z axis position accuracy | 0.02/0.025mm |

| X/Z axis repeatability | 0.01/0.012mm |

| X/Z axis travel | 360/750mm/1000mm/1500mm |

| X/Z axis fast feeding speed | 8/10 M/MIN |

| Tailstock sleeve travel | 150mm |

| Tailstock taper | MT5 |

| Dimension | 3160*1560*1730mm |

| weight | 3500kg |

The machine can move and process parts according to the programmed program. It integrates the latest technologies such as machinery, automation, computers, measurement, and microelectronics, and uses a variety of sensors, 2. The sensors used on CNC machine tools mainly include photoelectric encoders, linear gratings, which are mainly used to detect position, linear and angular displacement, speed, pressure, temperature, etc.

The machine can move and process parts according to the programmed program. It integrates the latest technologies such as machinery, automation, computers, measurement, and microelectronics, and uses a variety of sensors, 2. The sensors used on CNC machine tools mainly include photoelectric encoders, linear gratings, which are mainly used to detect position, linear and angular displacement, speed, pressure, temperature, etc.

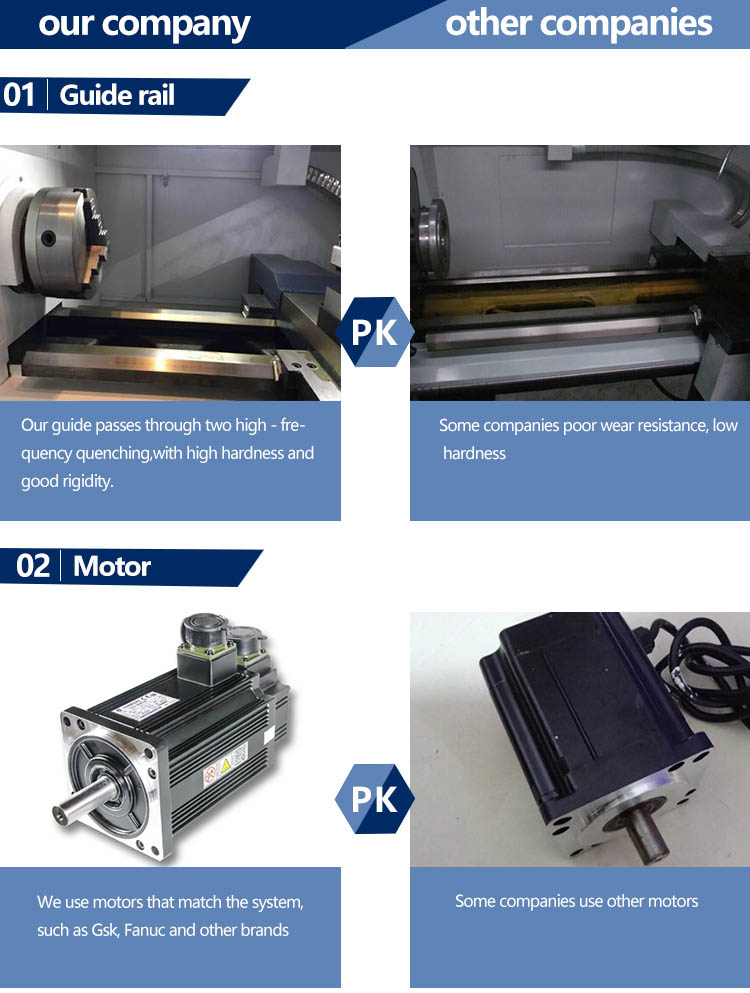

1. The machine tool itself has high precision, high rigidity and high productivity. 2. The machine tool has a high degree of automation, which can reduce labor intensity;

1. The machine tool itself has high precision, high rigidity and high productivity. 2. The machine tool has a high degree of automation, which can reduce labor intensity;