| Main technical parameters | GB4230 | ||

| Sawing range | Round steel | Φ300mm | |

| Square material | 300×300mm | ||

| Belt saw blade size | 3050*34*1.1 | ||

| Saw blade speed | 27, 45, 69m/min | ||

| working clamping | Hydraulic | ||

| Motor power | Main motor | 2.2kw | |

| Oil pump motor | 0.42kw | ||

| Cooling pump motor | 0.04kw | ||

| Package size | 1860×1000×1400 | ||

| NW/GW | 800kg | ||

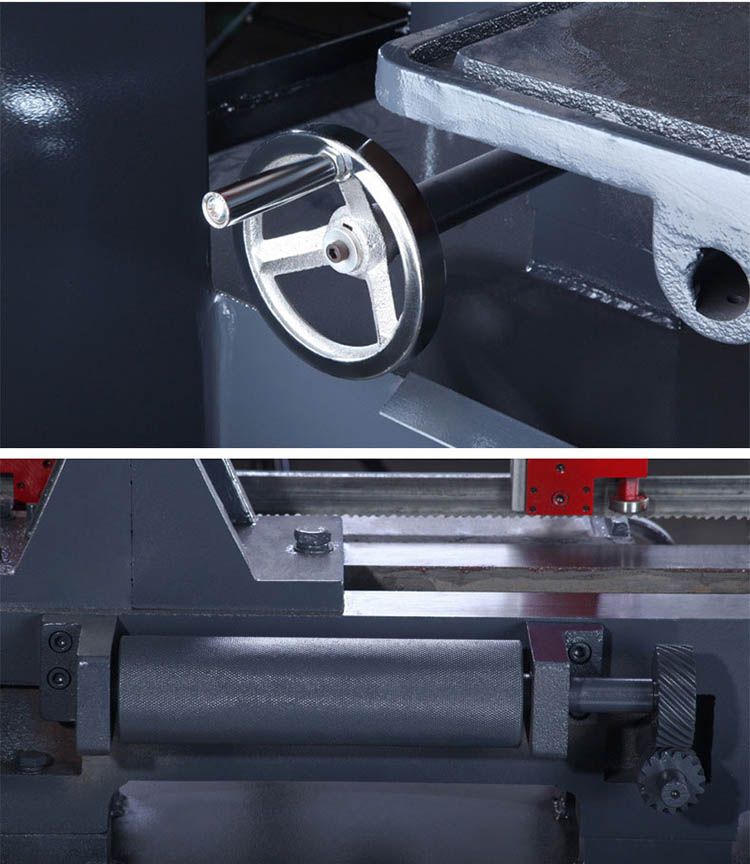

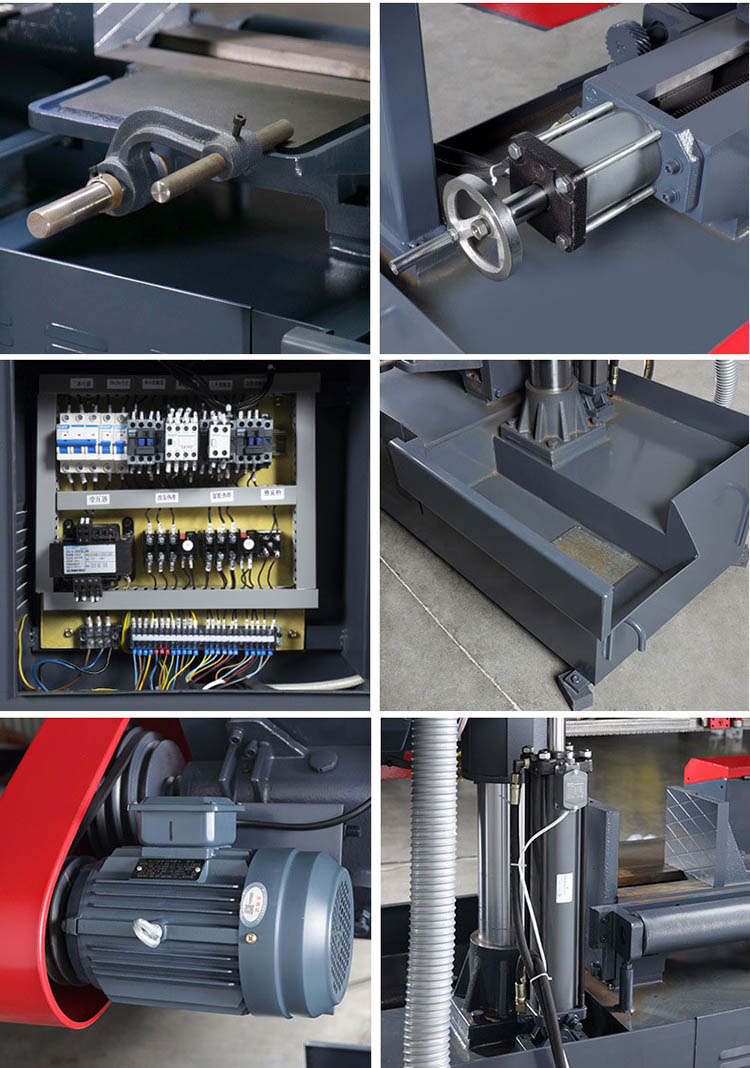

Double column horizontal metal band sawing machine, double column horizontal metal band sawing machine mainly The components are: bottom seat; bed, column; saw beam and transmission mechanism; guiding device; workpiece clamping; tensioning device; feeding frame; hydraulic transmission system; electrical control system; lubrication and cooling system. The hydraulic transmission system is composed of a hydraulic circuit composed of pumps, valves, cylinders, tanks, pipelines and other auxiliary parts. The lifting of the saw beam and the clamping of the workpiece are completed under electrical control. Through the speed control valve, the stepless speed regulation of the feed speed can be implemented to meet the needs of sawing workpieces of different materials. The electrical control system consists of a control loop composed of an electrical box, a control box, a junction box, a travel switch, an electromagnet, etc., used to control the rotation of the saw blade, the lifting of the saw beam, the clamping of the workpiece, etc., to make it follow a certain working procedure Realize the normal cutting cycle. The lubrication system must be lubricated according to the lubrication parts of the machine tool (wire brush shaft, worm gear box, active bearing seat, worm bearing, lifting cylinder upper and lower shaft, and movable vise sliding surface clamping screw)_requirement before starting. The worm gear and worm in the worm gear box are lubricated by a No. 30 oil bath, which is injected from the oil plug hole on the upper part of the worm gear box. The box surface is equipped with an oil mark. When the saw beam is at the lowest position, the oil level should be at the upper and lower limits of the oil mark between. The oil should be changed after a month of trial use, and then every 3-6 months. The lower part of the worm gear box is equipped with an oil drain plug.

Double column horizontal metal band sawing machine, double column horizontal metal band sawing machine mainly The components are: bottom seat; bed, column; saw beam and transmission mechanism; guiding device; workpiece clamping; tensioning device; feeding frame; hydraulic transmission system; electrical control system; lubrication and cooling system. The hydraulic transmission system is composed of a hydraulic circuit composed of pumps, valves, cylinders, tanks, pipelines and other auxiliary parts. The lifting of the saw beam and the clamping of the workpiece are completed under electrical control. Through the speed control valve, the stepless speed regulation of the feed speed can be implemented to meet the needs of sawing workpieces of different materials. The electrical control system consists of a control loop composed of an electrical box, a control box, a junction box, a travel switch, an electromagnet, etc., used to control the rotation of the saw blade, the lifting of the saw beam, the clamping of the workpiece, etc., to make it follow a certain working procedure Realize the normal cutting cycle. The lubrication system must be lubricated according to the lubrication parts of the machine tool (wire brush shaft, worm gear box, active bearing seat, worm bearing, lifting cylinder upper and lower shaft, and movable vise sliding surface clamping screw)_requirement before starting. The worm gear and worm in the worm gear box are lubricated by a No. 30 oil bath, which is injected from the oil plug hole on the upper part of the worm gear box. The box surface is equipped with an oil mark. When the saw beam is at the lowest position, the oil level should be at the upper and lower limits of the oil mark between. The oil should be changed after a month of trial use, and then every 3-6 months. The lower part of the worm gear box is equipped with an oil drain plug. Metal band sawing machine is mainly used for sawing various metal materials such as carbon structural steel, low alloy steel, high alloy steel, special alloy steel, stainless steel, acid-resistant steel, etc.

Metal band sawing machine is mainly used for sawing various metal materials such as carbon structural steel, low alloy steel, high alloy steel, special alloy steel, stainless steel, acid-resistant steel, etc.