| Describe | Unit | SM385 | |||

| Mechanic | Controller system |

| Fanuc 0i | Syntec | |

| Max maching diameter | mm | ¢38 | |||

| Stroke | mm | 210 | |||

| Main Spindle /Sub spindle RPM | rpm | 8000/8000 | 6000/6000 | ||

| Rapid traverse speed | m/min | 32(X1:24m/min) | 24 | ||

| Tools | O.D Tools | ea | 5×[□16×16] | ||

| Front Work Tools | ea | 3×[Ø25-ER16]+2×[Ø20-ER16] | |||

| Cross Driven Tools | ea | 4×[ER16] | |||

| Back end tools(fixed) | ea | 4×[Ø20-ER16] | |||

| Motors | Spindle motor | kw | 5.5/7.5 | 5.5 | |

| Sub Spindle motor | kw | 1.5/2.2 | 3 | ||

| Driven | kw | 1 | |||

| Cross | kw | 0.55/1.1 | 1 | ||

| Coolant motor | kw | 0.9 | |||

| Others | Coolant tank capacity | L | 200 | ||

| Lubrication tank capacity | L | 1.8 | |||

| Height from floor tospindle center | mm | 1000 | |||

| Dimension | (L) | mm | 2760 | ||

| (W) | mm | 1564 | |||

| (H) | mm | 1882 | |||

| Weight | kg | 4500 | |||

| NC Control | Controllable Axes | 7 axis/4axis | |||

| LCD | LCD 10.4" | ||||

| System standard parameters | Standard | ||||

| Rigid tapping | Standard | ||||

| Hand wheel | Standard | ||||

| Synchronous/hybrid control | Standard | ||||

| Helical interpolation | Standard | ||||

4. Automatic blank feeding and automatic blanking of finished products By configuring a bar feeder when feeding, and short/long parts catching when receiving, the machine tool can realize a "one person, multiple machines" mode of one person operation and multiple caretakers, which improves the automation of equipment and saves a lot of enterprises. Human resources can help a lot. In addition, the "cnc swiss type lathe machine" model also has the following outstanding features: 1) Multi-axis linkage interpolation function: to effectively improve processing efficiency and meet the processing of complex parts; 2) High-speed synchronous rotating guide sleeve: to meet the requirements of high-speed processing; 3) High enough accuracy: to meet the increasing accuracy requirements of aviation, precision instruments, communication equipment and other parts.

4. Automatic blank feeding and automatic blanking of finished products By configuring a bar feeder when feeding, and short/long parts catching when receiving, the machine tool can realize a "one person, multiple machines" mode of one person operation and multiple caretakers, which improves the automation of equipment and saves a lot of enterprises. Human resources can help a lot. In addition, the "cnc swiss type lathe machine" model also has the following outstanding features: 1) Multi-axis linkage interpolation function: to effectively improve processing efficiency and meet the processing of complex parts; 2) High-speed synchronous rotating guide sleeve: to meet the requirements of high-speed processing; 3) High enough accuracy: to meet the increasing accuracy requirements of aviation, precision instruments, communication equipment and other parts.

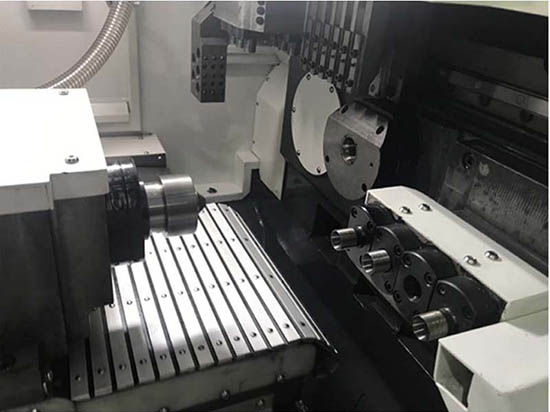

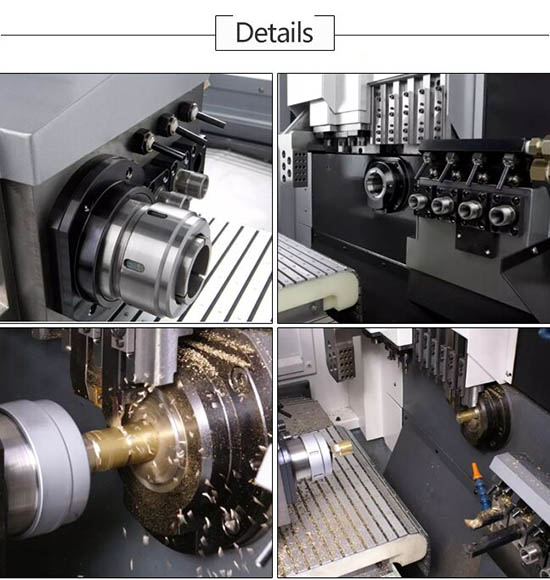

2. SM385 swiss type cnc lathe machine has high rigidity turning and milling, with one clamping that can realize the high rigidity of the workpiece outer circle, turning face, threading, grooving, cutting and transverse milling, drilling, tapping, and front face and Multiple compound processing capabilities such as drilling, tapping, and boring on the back end face after cutting.3. Double-spindle design for back processing after cutting and simultaneous processing For parts that require no convex and concave defects at the center of the rear end face of the workpiece, or for slender shaft parts that require the main and sub-spindles to be clamped and synchronously rotated, and for parts that require milling, drilling, boring, and tapping on the cut surface, double The spindle model can be fully qualified. In addition, the main and sub-spindles can be controlled simultaneously or independently processed.

2. SM385 swiss type cnc lathe machine has high rigidity turning and milling, with one clamping that can realize the high rigidity of the workpiece outer circle, turning face, threading, grooving, cutting and transverse milling, drilling, tapping, and front face and Multiple compound processing capabilities such as drilling, tapping, and boring on the back end face after cutting.3. Double-spindle design for back processing after cutting and simultaneous processing For parts that require no convex and concave defects at the center of the rear end face of the workpiece, or for slender shaft parts that require the main and sub-spindles to be clamped and synchronously rotated, and for parts that require milling, drilling, boring, and tapping on the cut surface, double The spindle model can be fully qualified. In addition, the main and sub-spindles can be controlled simultaneously or independently processed.